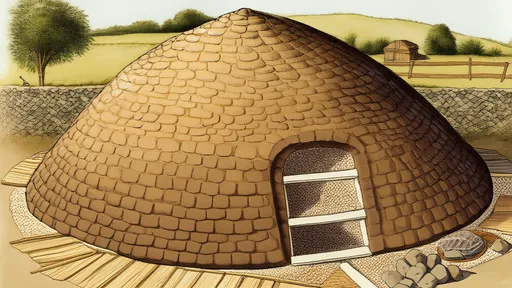

For centuries, clay ovens have been a cornerstone of traditional baking, offering a unique combination of rustic charm and efficient heat retention. The construction of a bread oven, particularly one with a clay dome, is both an art and a science. Understanding the thermodynamics behind these structures is essential for creating an oven that bakes evenly, retains heat effectively, and stands the test of time.

The Foundations of Clay Oven Design

At the heart of every successful bread oven is a well-designed dome. The shape is not arbitrary—it plays a crucial role in heat circulation and retention. A properly constructed clay dome ensures that heat radiates evenly, allowing bread to bake with a crisp crust and a soft interior. The thickness of the clay walls, the curvature of the dome, and the materials used all contribute to the oven's thermal efficiency.

Clay, as a material, has excellent heat retention properties. Unlike metal, which conducts heat rapidly, clay absorbs and releases warmth slowly, creating a stable baking environment. This characteristic makes it ideal for bread ovens, where consistent temperatures are key. However, not all clay is the same. The composition of the clay mixture—often blended with sand or straw—affects its insulating properties and durability.

The Science of Heat Flow in a Clay Dome

Thermodynamics governs how heat moves through the oven. When a fire is lit inside the dome, the flames heat the clay walls, which then radiate that energy inward. The dome’s curvature ensures that heat is reflected back toward the center rather than escaping upward. This creates a convection effect, where hot air circulates naturally, enveloping the bread in an even, all-around bake.

One of the challenges in designing a clay dome is minimizing heat loss. A well-built oven will have a thick enough layer of clay to store sufficient heat but not so thick that it takes an impractical amount of fuel to reach baking temperatures. The entrance of the oven also plays a role—too large, and heat escapes; too small, and loading bread becomes difficult. Finding the right balance is key.

Traditional Techniques Meet Modern Insights

While the principles of clay oven construction have been passed down through generations, modern builders have refined these techniques with a deeper understanding of thermodynamics. For example, some now incorporate insulating layers beneath the clay to reduce heat loss into the ground. Others experiment with different clay-to-sand ratios to optimize thermal mass without compromising structural integrity.

Another innovation is the use of refractory materials—substances that withstand high temperatures—mixed into the clay. These can enhance durability, especially in ovens used frequently. Yet, despite these advancements, many artisans still prefer traditional methods, valuing the authenticity and time-tested reliability of pure clay construction.

The Role of the Chimney and Ventilation

A well-designed chimney is essential for controlling airflow and smoke. Without proper ventilation, the oven can become smoky, making it difficult to maintain a clean burn. The chimney’s placement and size affect how efficiently the fire draws in fresh air and expels combustion byproducts. Too narrow, and the fire may smolder; too wide, and heat escapes too quickly.

Some builders incorporate a small flue at the front of the oven to help direct smoke upward while allowing heat to remain trapped inside. This subtle design element can make a significant difference in both baking performance and user comfort.

Building for Longevity and Performance

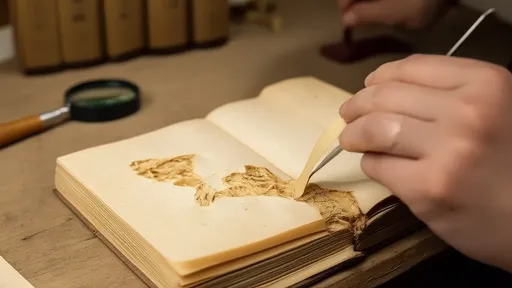

A bread oven is an investment, and its lifespan depends heavily on construction quality. Cracks in the clay can develop if the dome dries too quickly or if the mixture lacks sufficient reinforcing fibers. To prevent this, many builders recommend a slow curing process, allowing the clay to dry gradually over several days or even weeks.

Seasoned oven builders also emphasize the importance of a solid foundation. Since clay ovens are heavy, the base must be sturdy enough to support the weight without shifting. Brick, stone, or reinforced concrete are common choices, each offering different advantages in terms of stability and insulation.

The Joy of Baking in a Clay Oven

Beyond the technical aspects, there’s something deeply satisfying about baking in a clay oven. The way heat lingers, the aroma of wood-fired bread, and the connection to ancient traditions all contribute to the experience. Whether used in a backyard or a professional bakery, a well-built clay dome oven brings a touch of artistry to the craft of baking.

For those considering building their own, patience and attention to detail are crucial. Every step—from mixing the clay to shaping the dome—affects the final result. But for those willing to put in the effort, the reward is an oven that not only bakes exceptional bread but also stands as a testament to the timeless union of craftsmanship and science.

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025