The delicate dance between modern technology and ancient techniques in bronze artifact restoration has become a focal point for conservators worldwide. As museums and archaeological institutions grapple with preserving these cultural treasures, a nuanced conversation emerges about how to balance cutting-edge science with time-honored methods. The oxidation process that creates the iconic patina on bronze works also threatens their structural integrity when left unchecked, forcing conservators to make difficult decisions about intervention.

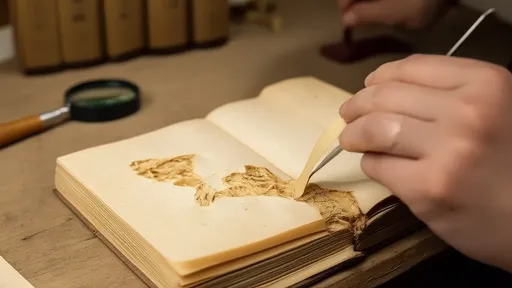

In laboratories across Europe, laser cleaning systems now remove corrosion with micrometer precision, leaving the original surface untouched. This space-age technology represents a quantum leap from the chemical baths and manual scraping that dominated restoration for centuries. Yet some conservators argue that these new methods, while impressive, lack the subtlety required for certain artifacts. The patina itself tells a story - layers of interaction between metal and environment that constitute an object's biography. Overzealous cleaning risks erasing this history as surely as the corrosion would destroy the artifact.

The British Museum's approach exemplifies this tension. Their conservation team employs scanning electron microscopes to analyze corrosion layers before deciding on treatment. Some objects receive the full technological treatment: micro-abrasion followed by protective polymer coatings. Others get gentler care - careful swabbing with dilute formic acid, a method little changed since Victorian times. The determining factor often comes down to the artifact's intended future: pieces destined for display might receive more aggressive treatment than those going into controlled storage.

Chinese conservators have developed particularly sophisticated hybrid techniques. At the Shanghai Museum, ancient recipes for bronze preservation - some recorded in Song Dynasty texts - inform modern electrochemical stabilization methods. The traditional "wucai" five-step process, involving successive applications of different plant-based solutions, has been adapted to work in conjunction with modern corrosion inhibitors. This fusion respects the artifact's cultural context while ensuring long-term preservation.

Controversy arises when considering what constitutes "authentic" preservation. Radical cleaning can leave bronze looking factory-fresh, stripping away not just corrosion but centuries of history. Some institutions now advocate for "stabilization without aesthetic intervention" - halting deterioration without attempting to restore appearance. This philosophy acknowledges that every scratch and discoloration contributes to an object's narrative. The debate echoes broader questions in art conservation about whether we should preserve artifacts as they were made or as time has shaped them.

Technological advances continue to push boundaries. 3D mapping allows conservators to document surface details before treatment begins, creating digital records that survive the physical artifact. New nanocrystalline coatings promise protection without altering appearance. Yet for all these innovations, many conservators still keep cotton swabs and dental tools in their kits - simple technologies that offer control no laser can match. The future likely lies not in choosing between old and new methods, but in developing the wisdom to know when each serves best.

As climate change accelerates corrosion rates worldwide, these decisions grow more urgent. Bronze artifacts that survived millennia relatively unscathed now face unprecedented threats from pollution and shifting weather patterns. The conservation community's response - blending ancestral knowledge with twenty-first century innovation - may determine how much of our metallic heritage endures for future generations. What emerges is neither pure science nor pure tradition, but a third way that honors both the artifacts and the cumulative knowledge of those who preserve them.

By /Jul 9, 2025

By /Jul 9, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025

By /Jul 8, 2025